Robotics in Modern Manufacturing: Revolutionizing Production

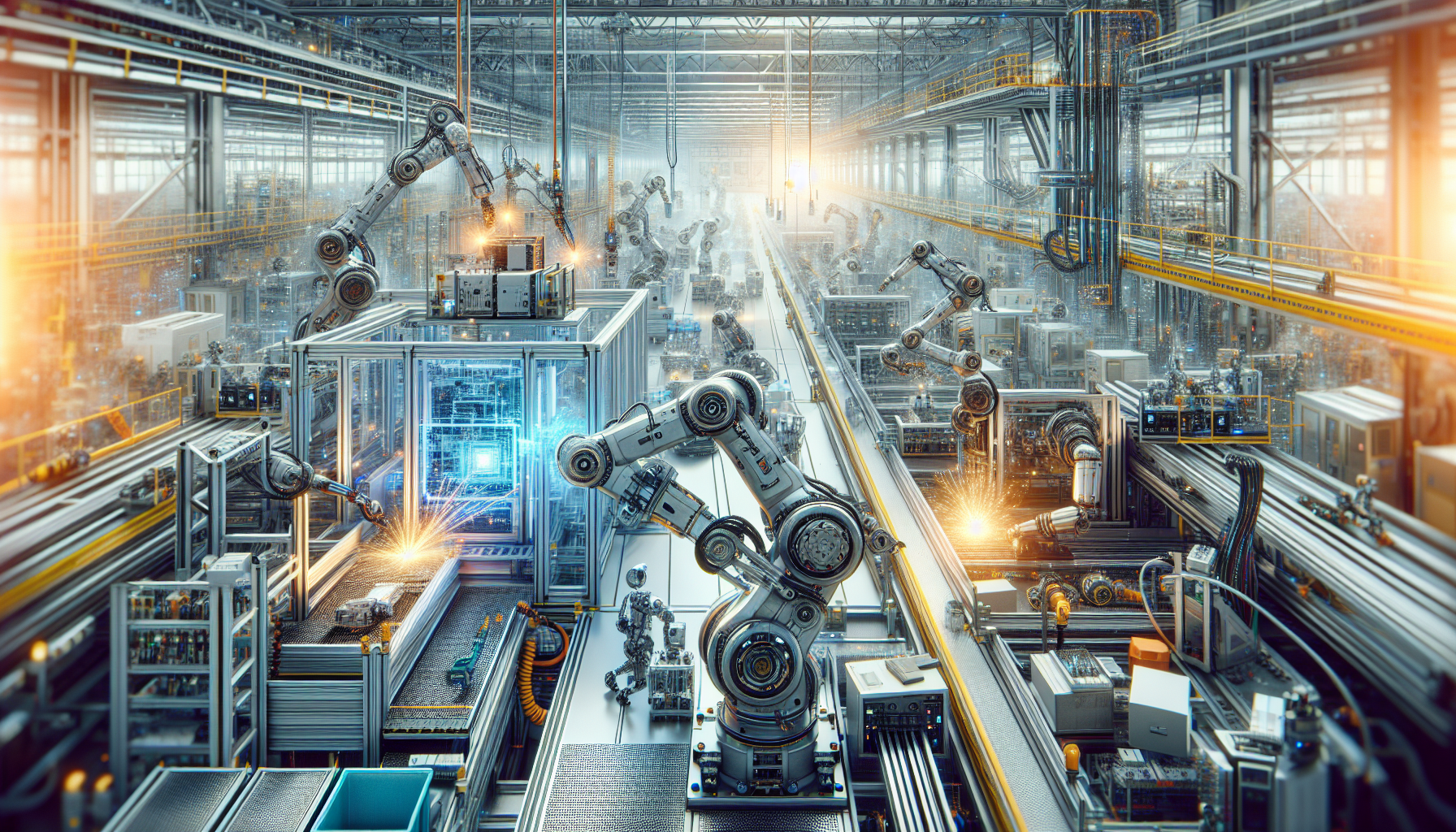

As industries pursue greater efficiency, the metamorphosis brought forth by robotics in modern manufacturing is undeniable. Traditional manufacturing processes are evolving, facing challenges like labor shortages and the demand for precision. An example of this transformation can be seen in the automotive industry, where companies have implemented robotic arms to enhance productivity and ensure quality control.

Pain Points in Manufacturing

Manufacturers often grapple with issues such as high labor costs and the intricacies of maintaining product quality. These obstacles hinder operational efficiency, compelling organizations to adopt innovative solutions. The utilization of robotics addresses these pain points, allowing for higher production rates and reduced human error.

Solutions in-depth Analysis

A robust solution to the challenges faced in modern manufacturing is integrating robotics. By following these steps, businesses can effectively implement robotics:

- Assess the specific manufacturing processes and identify areas suitable for automation.

- Select appropriate robotic systems, focusing on flexibility and scalability.

- Implement sophisticated sensors and **machine learning** algorithms to improve robot adaptability to production changes.

Comparison of Solutions

| Parameter | Solution A | Solution B |

|---|---|---|

| Security | High | Medium |

| Cost | High Initial Investment | Lower Initial Cost |

| Suitable Scenarios | Complex Assembly | Simple Tasks |

According to a recent report by IEEE, the adoption of robotics in modern manufacturing is projected to increase by 25% by 2025, significantly optimizing manufacturing processes and reducing costs.

Risk Warnings

Despite the numerous benefits of automation through robotics, risks do exist. Organizations should consider potential downtime due to technical failures. Proactive maintenance and advanced training for staff are essential to mitigate these risks effectively.

In conclusion, robotics in modern manufacturing presents a tremendous opportunity to enhance productivity while addressing common challenges. By exploring innovative solutions, organizations like theguter can stay ahead in a competitive landscape.

FAQ

Q: How can robotics improve efficiency in manufacturing?

A: Robotics in modern manufacturing streamlines processes, minimizing human error and improving production rates.

Q: What are the risks associated with implementing robotics?

A: Risks include potential downtime and the need for ongoing maintenance and training of staff.

Q: Is it cost-effective to switch to robotic automation?

A: While initial costs may be high, robotics in modern manufacturing leads to long-term savings and efficiency gains.